Yantai Kaishi Industry Co., Ltd. Cleaner Production Audit Publicity

Yantai Kaishi Industrial Co., Ltd. is a large and medium-sized enterprise integrating cobalt metal hydrometallurgy, scientific research and development, production and operation, and comprehensive utilization of resources. The registered capital of the company is 185 million yuan. The total assets of the company are 427 million yuan. There are 406 employees, including 87 professional and technical personnel; it covers an area of 100 acres (66,000 square meters), and the factory building area is 37,000 square meters.

Kaishi uses the rich cobalt ore originating in Africa, adopts the international advanced hydrometallurgical process and the non-hydrochloric acid system electrowinning product production process (patent) with independent intellectual property rights, and multi-stage purification and purification production facilities, which not only make the products The grade and quality are in the advanced position in China, creating a technical support platform for the greater development of production.

Kaishi has formulated and implemented a set of strict quality management system, which has passed ISO9001:2008 and QC080000 quality management system certification. This indicates that the company has the ability to ensure continuous and stable production in line with Chinese\/enterprise standards and European RoHS regulations requested product.

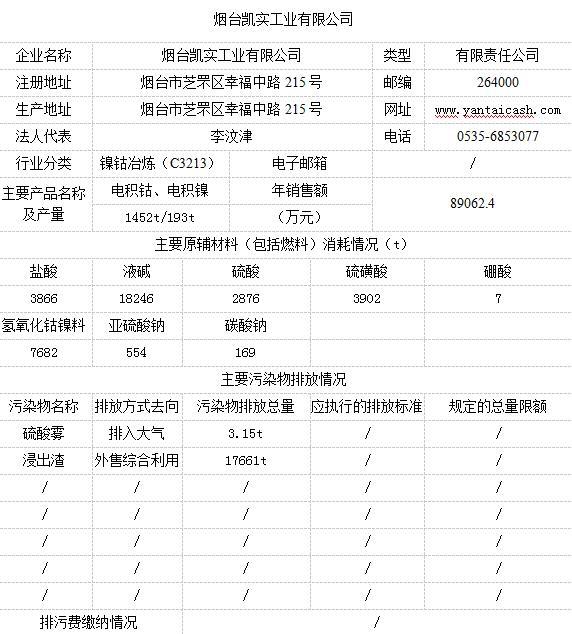

In accordance with the relevant regulations of the Cleaner Production Promotion Law of the People's Republic of China and the Cleaner Production Audit Measures, our company is an auditing enterprise in the list of mandatory cleaner production enterprises in Laizhou City. On June 3, 2020, our company began to implement cleaner production audits , Now the company's production and sewage conditions are publicized to the public, and all sectors are welcome to supervise and guide.

The company's waste gas is mainly the acid mist generated by the leaching process and the electrowinning process, as well as the boiler flue gas. The acid mist generated by the leaching process and the electrowinning process is purified by the acid mist absorption tower and then discharged up to the standard. The boiler flue gas is discharged up to the standard through the exhaust pipe. The company's wastewater is mainly production wastewater and domestic sewage. The production wastewater is reused for production and boiler make-up water after heavy metal recovery and high salt water 3-effect evaporation, and is not discharged outside. The domestic sewage is treated in a septic tank and then discharged into the sewage pipe network. The company The solid waste is mainly leaching residue and domestic waste. The leaching residue is a general solid waste, all sold out, and the domestic waste is handled by the sanitation department.